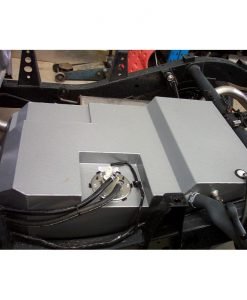

ARB – Recovery Point 8T Mitsubishi L200 Triton MQ / MR 2015on – RHS – 4×4 Only

Strong, reliable recovery points are essential for off road driving but the lack of industry standards regarding rated tow points has caused confusion among four wheel drivers for many years. With this in mind, ARB has sought to set an industry benchmark for how recovery points are designed, tested and selected by 4WDers. ARB’s recovery point range seeks to address issues surrounding generic tow points and their unsuitability for a range of recovery situations.

These issues include questionable and untested mounting locations, confusion regarding the selection of rated shackles and straps, and the inability of generic tow points to safely handle stresses generated by an angled pull during vehicle recovery. ARB aims to make it easy to find the correct recovery point for each individual customer with an engineered ‘Recovery Train’ in which each vehicle specific recovery point is rated for use with a 4.75t rated bow shackle and 8000kg snatch strap.

Research and Design

Each ARB recovery point undergoes considerable research and design involving actual vehicle chassis samples and CAD data relating to critical front sections of the vehicle. Dozens of designs are explored, with the more promising models built into prototypes and tested on the actual vehicle chassis using ARB’s various load and destructive testing equipment.

Vehicle Specific Mounting

Some vehicle models demand very complex mounting systems to ensure fitment does not affect air bag deployment in the event of an accident. With months of design and testing dedicated to each individual recovery point, ARB’s engineers ensure that the crash pulse of the vehicle remains unaffected, whilst also ensuring the recovery points are fitted in the optimal location to handle the stresses experienced during vehicle recovery.

Rated for Angled Recovery

ARB recovery points are rated in an angled direction of pull and this has been achieved for angles up to the maximum turn angle of the front wheels of the vehicle. The design features a long slot as it allows the bow of the shackle to be fed through and the strap attached via the pin instead of the bow. This allows the shackle to pivot within the recovery points to avoid side loads on the pin.

Features:

- Modification of under bar panels may be necessary on some vehicles fitted with an ARB bull bar

- Vehicle specific design, with load and destruction tests conducted on the chassis of the MQ Triton

- Can only be mounted on the right side of the chassis. Can only be fitted in combination with ARB bar.

- Eye constructed from 20mm high grade 350MPa steel for maximum strength and durability

| Gewicht | 5 kg |

|---|---|

| Afmetingen | 31 × 26 × 16 cm |

Enkel ingelogde klanten die dit product gekocht hebben, kunnen een beoordeling schrijven.

Beoordelingen

Er zijn nog geen beoordelingen.